It’s hard to believe that 2016 is already coming to an end. Time has flown this year as it usually does. With that said, the holidays are a good time to look ahead at the year to come, and to reflect on the year just passed — and what a year it has been for all of us!

usually does. With that said, the holidays are a good time to look ahead at the year to come, and to reflect on the year just passed — and what a year it has been for all of us!

One of the major milestones in our own year here at Ed Fagan Inc. was the expansion of stock inventory in two lines of high performance alloys in our roster of available alloys and super alloys, Hiperco 50/50A and Super Invar.

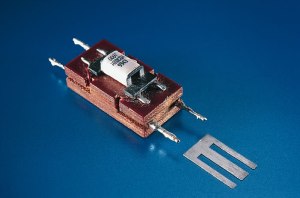

Originally known as permendur, Hiperco 50 is a soft-magnetic alloy made of iron and cobalt, generally 49% of each, and 2% vanadium for improved mechanical properties and machinability, with the occasional addition of trace volumes of manganese, niobium, and silicon to further improve machinability. Though not a new material, having been invented in the 1920s, Hiperco 50 is being found in more applications (add link back to “being found in more applications”) thanks to its extremely high magnetic saturation, useful in many engine and aerospace applications.

Available in plate, round bar, and sheet form, Super Invar is another alloy that is increasingly sought after. An alloy of 63% iron, 32% nickel, and 5% cobalt, this alloy is strong and has excellent thermal properties — in fact, of every nickel-based alloy, Super Invar has the lowest coefficient of thermal expansion. This makes it ideal for structural applications in a wide range of optical instruments, lasers, gyroscopes, and more.

While the stock inventory expansions of these highly sought after materials was a big moment for us, it was far from all that we accomplished this year. In April, June, and October we, along with many others in the various manufacturing industries, celebrated Earth Day, National Safety Month, and Manufacturing Day.

Perhaps most importantly of all, in August we were able to investigate the entirety of our vast and complex supply chain and confirm that Ed Fagan is a completely conflict mineral-free business.

We would like to thank everyone who helped to make 2016 such a great year for us. Have a happy, safe, and healthy holiday season — we’ll see you in 2017!

Curious about researching our metals and alloys while you have time off of your feet? Read more from Ed Fagan by continuing to follow our blog, LinkedIn, and Twitter!

greener choices, but it hasn’t always been easy. Activists began lobbying for environmental protections since the industrial revolution. In April of 1970 the first formal event,

greener choices, but it hasn’t always been easy. Activists began lobbying for environmental protections since the industrial revolution. In April of 1970 the first formal event,

You must be logged in to post a comment.